Table of Content

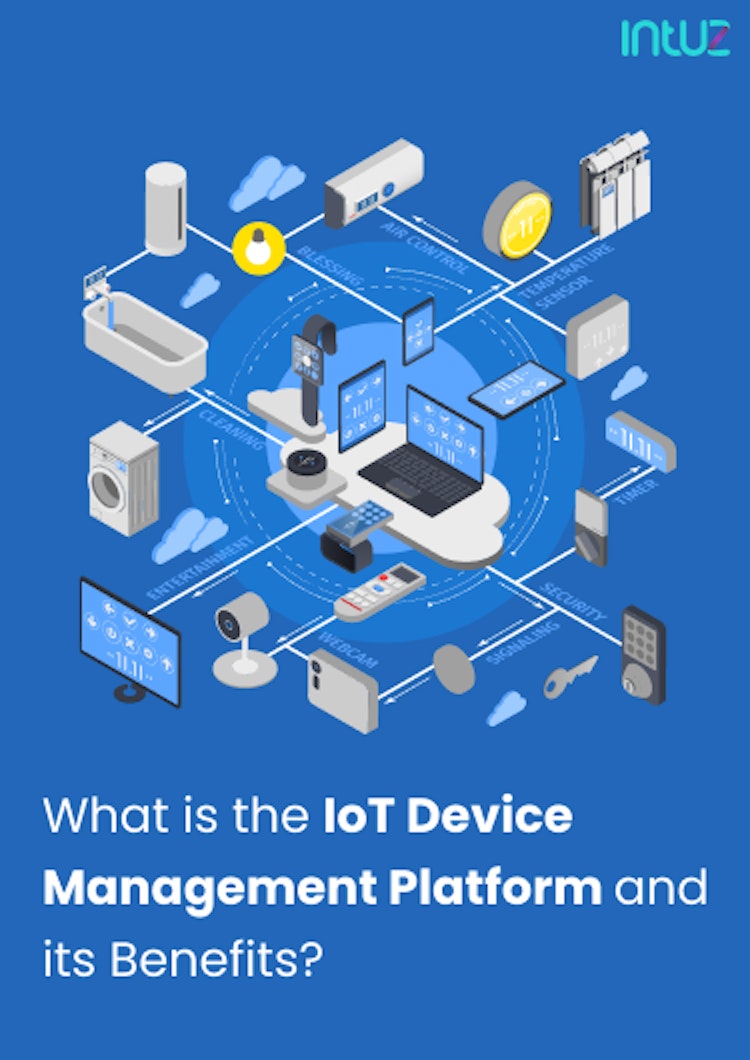

It is no surprise how IoT has taken the world by storm. Defined as a paradigm where physical objects equipped with sensors, processors, and actuators communicate and exchange data with other devices and systems over the internet, these objects range from sophisticated industrial tools to ordinary household products.

Statista states more than 75 billion IoT-connected devices will be in use by 2025. IoT devices collect and analyze data acquired from their environments. The data fetched will be interpreted locally in the cloud or on-premise.

But how does the IoT ecosystem function? Sensors and actuators, specifically, enable interaction with the physical world. For instance, an actuator creates smart motors and applications for robots. Attach the smart motor to any device, power it up, and the actuator lets you control the device from your desktop browser.

Actuators are essential in the quickly developing IoT market. They help ensure equipment safety, enhance production procedures, and increase corporate efficiency. In the following section, we will help you overcome technological barriers with an in-depth analysis of actuators.

In this short guide, we will look at the different actuators used in an IoT ecosystem, their advantages, and how to choose suitable actuators for your business.

What are Actuators in IoT?

An actuator is a mechanical or electromechanical device that transforms energy into motion. It accomplishes this by fusing an energy source with an electrical signal. In short, it is the part of any machine that makes movement possible.

In IoT, an actuator is responsible for the physical movement of an object. It can be a device that can move things and is powered using different sources such as the battery, electric, or manually-generated energy.

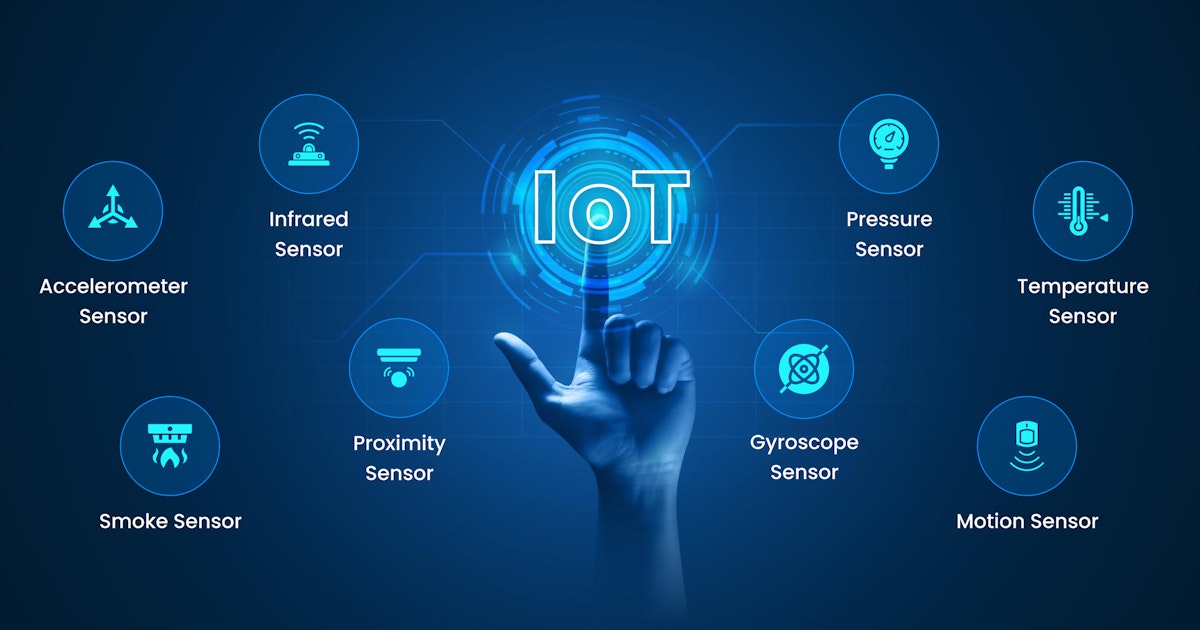

Think of actuators as the opposite of sensors:

- Sensors: Convert physical input into electrical signals

- Actuators: Convert electrical signals into physical output

The types of devices that use actuators

Actuators control everything around us. If you look around, they are part of almost everything that facilitates our everyday life. Over the years, they have shown their value and dependability through usage in connected machines. Want to know more? The following devices use actuators:

1. Stepper motors

The primary function of these actuators is to translate digital pulses into mechanical motion. Robots, smart tools, and automated cutting devices frequently use stepper motors.

2. Electric motors

Any component of a machine or appliance that converts electrical energy into motion has at least one actuator. For instance, those found in blenders, refrigerators, ventilation fans, and electric cars contain at least one actuator.

3. Hydraulic cylinders

These machines move linearly and are propelled by a tube, piston, and rod. Bulldozers, backhoes, and excavators are just a few machines you know in real life that use hydraulic motion to move their parts.

Enhance Your IoT Project with Expert Actuator Integration!

Let's Get StartedThe different types of actuators in IoT

Various kinds of actuators can be used in a typical IoT ecosystem. These can be categorized according to the motion they create and the power source they employ. Here is the top list of actuator options:

1. Motion

The two primary motions that actuators can produce are linear and rotary. Come, let us study them both in greater detail:

a. Linear actuators

Tools that generate movement along a straight line are known as linear actuators. They typically appear in hydraulic or pneumatic equipment and might be mechanical or electrical. A linear actuator is usually present in any device that needs to move in a straight line.

A nut, cover, and sliding tube make up a primary linear actuator. While the nut and cover provide the interlocking motion that ensures the actuator moves in a straight line, the sliding tube creates room for action.

This simple device is the basis for straight movement, while other sophisticated linear actuators will include additional elements.

b. Rotary actuators

Rotary actuators generate a circular motion as opposed to linear actuators. Since most machines use these rotating components to complete a turning movement, they are referred to as "rotary" machines. If a machine needs to move up, down, forward, or backward, they are frequently employed in tandem with a linear actuator motor.

Hydraulic or pneumatic systems power several rotational actuators in addition to the majority powered by electricity. Electric fans, windscreen wipers, and industrial equipment moving products from one location to another use rotational actuators.

2. Source of energy

We may also arrange actuators by the system or power source that drives it to separate various types of actuators further. The most popular actuators categorized according to energy sources are listed below:

a. Hydraulic actuators

With the help of a cylinder or fluid motor, hydraulic actuators can provide mechanical motion, producing linear, rotatory, or oscillatory motion. A hydraulic actuator can make a significant amount of force since liquids are essentially challenging to compress.

A force is applied to the bottom of the piston, which is also inside the hydraulic cylinder of the actuator, when the fluid enters the lower chamber of the cylinder.

The sliding piston is moved upward, and the valve is opened by the pressure, which carries the piston in the opposite direction of the force produced by the upper chamber's spring.

The disadvantage of these actuators is the requirement for several auxiliary components and the potential for fluid leakage.

Advantages

- It is helpful for clamping, welding, and similar activities.

- It is best utilized to raise or lower autos in car transport vans.

- A hydraulic actuator is capable of producing a lot of force and speed.

Disadvantages

- The cost of hydraulic actuators is high.

- Leaks in the hydraulic fluid can reduce performance and create cleaning problems.

- Heat exchangers, noise reduction technology, and high maintenance systems are needed to complement its functioning.

b. Pneumatic actuators

Compressed air energy is transformed into mechanical motion by pneumatic actuators. In this instance, compressed air or gas is introduced into a chamber to increase pressure.

A straight or circular mechanical motion results when this pressure rises above the necessary pressure levels compared to the atmospheric pressure outside the chamber. This happens when the piston or gear is moved kinetically in a controlled manner.

Air cylinders, pneumatic cylinders, and air actuators are some examples. Since no power source needs to be kept in reserve for operation, they are less expensive and frequently more powerful than other actuators and can start or stop quickly.

These actuators are commonly used in conjunction with valves to regulate the amount of air that passes through the valve. They provide a significant amount of force with only modest pressure changes.

Advantages

- A pneumatic actuator is a cheap alternative and best utilized in high-temperature situations - where using air is safer than chemicals.

- It is dependable, has a long working life, and requires little maintenance.

- The motion starts and stops very quickly, making the actuator reliable.

Disadvantages

- The pressure loss could reduce its effectiveness.

- The air compressor ought to be operating nonstop.

- Air requires upkeep and is subject to pollution.

c. Electric actuators

Such actuators need electricity to function. Famous examples include robotics equipment, manufacturing gear, and electric vehicles. Since the flow of electrical power is steady, electric actuators produce accurate motion like pneumatic actuators do.

Advantages

- Due to an electric actuator's ability to automate industrial valves, it has many uses across numerous sectors.

- Since there are no fluid leaks, it is safer to operate and makes less noise.

- It offers the highest control and precise positioning and may be reprogrammed.

Disadvantages

- An electric actuator is costly to deploy and maintain.

- The type of environment has a significant impact on its working.

The two types of electric actuators are:

i. Electromechanical actuators: When an electric motor replaces the control knob or handles on a mechanical actuator, the device is called an electromechanical actuator. The motor's rotating motion causes linear displacement.

ii. Electrohydraulic actuators: Electrohydraulic actuators are self-contained actuators that only use electrical power, unlike hydraulic systems. In essence, they are utilized to operate tools like multi-turn valves or electric-powered construction and excavation machinery.

The electrical actuators were initially created for the aerospace sector. However, today they are used in many other industries - wherever hydraulic power is employed.

d. Thermal actuators

A non-electric motor known as a thermal actuator produces linear motion in reaction to temperature variations. A piston and a thermally sensitive substance make up its essential parts. The thermally sensitive materials start to expand in response to a rise in temperature, which forces the piston out of the actuator.

Similarly, when the temperature drops, the thermally sensitive components within the contract cause the piston to withdraw.

Besides operating latches, switches, and open or close valves, these actuators can be utilized for other functions. They have a wide range of uses, mainly in the solar, automotive, agricultural, and aerospace sectors.

e. Magnetic actuators

Actuators that use magnetic effects to move a component are known as magnetic actuators. The movement in magnetic actuators is brought around by the magnetic field. It is known as the Joule effect and sometimes occurs simply with a coil's placement in a static magnetic field. The Laplace-Lorentz force causes constant motion of the actuator.

They often fall into the following groups: electromagnetic actuator, moving coil actuator, magnet actuator, and moving iron actuator. They are lightweight yet capable of making powerful movements.

f. Mechanical actuators

Mechanical actuators move by transforming one type of motion, such as rotary motion, into another, such as linear motion. Consider a rack and pinion as an example. A chain block hoisting weight is another illustration in which a load is raised using the mechanical motion of the chain.

Mechanical actuators depend on the interactions of the structural elements that make them up, such as gears and rails or pulleys and chains. Among the benefits are high dependability, ease of use, more straightforward maintenance, and improved positioning precision. Actuators can be classified as hydraulic, pneumatic, or electronic.

g. Supercoiled polymer actuators

Actuators made of supercoiled polymer are a relatively recent addition to the various forms of actuators.

Because they can mimic the motion of human muscle using a coil that contracts and expands when heated or cooled, they are employed in robotics and prosthetic limbs.

The anatomy of actuators in IoT

An actuator is a machine or part of a machine used to convert externally-available energy into motion based on the control signals. It is similar to how hands and legs enable humans to move around and perform tasks. Actuators allow IoT devices to undertake various mechanical movements. So, what does an actuator do? Typically, an actuator comprises:

a. Power converter

If the energy source attached to the actuators is not regulated, it requires additional apparatus for regulation and converting it into a form suitable for the actuation action. Solid-state power electronic converters and hydraulic valves are the top examples of power actuators.

b. Energy source

Without energy, actuators will not be able to do any work. They draw either mechanical or electrical power from external sources for carrying out their tasks. The energy available to the actuator can be unregulated or regulated depending on the IoT project.

c. Controller

Besides enabling the power conversion operation, a control unit is responsible for actuating signal generation. In some systems, it offers the users an interface that provides inputs or keeps the system status in check.

d. Load

The mechanical system attached to the actuator that uses motion is called load. Parameters such as speed and force are precisely tuned out before interfacing an actuator with the load.

Use Cases of Actuators in IoT

The combination of sensors and actuators in IoT creates powerful, responsive systems across various industries. Let's explore some compelling use cases:

1. Smart Home Automation

In a smart home, sensors detect environmental conditions while actuators adjust them for optimal comfort and efficiency.

Example: A smart thermostat system

Sensors: Temperature sensors, occupancy sensors

Actuators: HVAC control units

Process: The temperature sensor detects that the room is too warm. The occupancy sensor confirms someone is present. The system sends a signal to the HVAC actuator to lower the temperature.

2. Industrial Automation

In manufacturing, IoT systems can optimize production processes and enhance safety.

Example: Predictive maintenance in a factory

Sensors: Vibration sensors, temperature sensors on machinery

Actuators: Automated lubrication systems, emergency shut-off valves

Process: Vibration sensors detect unusual patterns in a machine. The system activates the lubrication actuator to apply oil. If the issue persists, it triggers the emergency shut-off valve to prevent damage.

3. Agriculture

IoT in agriculture, often called precision agriculture, optimizes crop yield and resource use.

Example: Smart irrigation system

Sensors: Soil moisture sensors, weather stations

Actuators: Water pumps, sprinkler systems

-Process: Soil sensors detect low moisture levels. The system checks weather data for upcoming rain. If no rain is expected, it activates the water pumps and sprinklers to irrigate the crops.

4. Healthcare

In healthcare, IoT devices can monitor patients and administer treatment automatically.

Example: Automated insulin delivery for diabetes patients

Sensors: Continuous glucose monitors

Actuators: Insulin pumps

Process: The glucose monitor detects rising blood sugar levels. It signals the insulin pump actuator to release a precise dose of insulin, maintaining optimal blood sugar levels.

5. Smart Cities

IoT systems in urban environments can improve efficiency and quality of life for residents.

Example: Intelligent traffic management

Sensors: Traffic cameras, vehicle counters

Actuators: Traffic light controllers, digital signage

Process: Sensors detect heavy traffic building up on one road. The system adjusts traffic light timings via actuators to alleviate congestion. It also updates digital signs to redirect traffic to less congested routes.

How to choose the right actuators

IoT technology is in a state of constant change. Therefore, it is essential to consider all aspects of actuators before picking one for your IoT application development project. Moreso, the need for actuators has grown manifold. Wherever you look, you can see hydraulic, pneumatic, or electric actuators in various IoT applications.

In addition, the vast array of actuators makes it difficult for industrial engineers to select the best type for their application. There is a misconception that you only need one actuator for a single project. However, that is not true.

Given the technological advancements, using more than one option for your IoT project is possible. If you are confused about making the right choice, fret not.

Therefore, making the optimal choice for your equipment requires an understanding of the various actuator types. We have listed down some variables that will assist you in making the ideal choice because each sort has a specific use and energy requirement:

1. Determine the amount of force required

What is the object's weight to be moved or lifted in your IoT application project? Do you require mini linear actuators with a force capacity of 15 lbs? Or would industry heavy-duty linear actuators capable of moving forces up to 2,200 lbs do? To make the right choice, use our force calculator to calculate your real force.

2. Calculate the distance the actuator must move

This "distance" is called the stroke length in an actuator, and it calculates how far the actuator will move in one direction. The stroke could range from 1" to 60."

For instance, actuators with rods are better for the extension of loads. On the other hand, rodless actuators have a stroke length roughly equal to that of the overall assembly, but they have the potential to carry a higher load.

3. Identify the speed required

Does your IoT project need to move slow or fast? The speed of a linear actuator - for instance - is measured in the distance per second. The higher the force, the slower the IoT actuator will move. Force and speed trade-off against each other - you must remember that before deciding what actuator you want to use.

4. List down all your IoT project requirements

First, work out your project's technical specifications to gauge the best actuator for the job. For example, track actuators are excellent for tight spaces where a sliding block makes sense due to its fixed length.

On the other hand, a rod-style actuator extends and retracts. It has greater precision than other linear actuators, which is a plus in repeatability and accuracy. Choose an actuator that helps you carry out your tasks comfortably.

5. Consider the directional force required by the actuator

Whether you want your actuator to work in only one direction or want it to use force up and down or back and forth, that will dictate whether you should opt for a double or single-acting actuator.

A double-acting actuator can do a full load in both directions, and a single-acting actuator can do the job in a single direction. So the first real question is - do you want your actuator to travel in both directions?

6. Check out the working space for the actuators

Actuators without roads - for example - have a smaller footprint and are often favored within the processing environments where space does not cause any hindrance.

7. Define the availability of the device's power source

Your power source's compatibility is another factor you must consider when picking an actuator for your IoT project. Electric actuators would likely be the most excellent option if you owned an industrial location with an electricity source. Pneumatic or hydraulic types are options if there are no electrical sources nearby or if you require fully functional equipment without electricity.

8. Check out what type of movement your IoT device will undertake

The movement range your equipment requires is crucial when selecting an actuator. The motion may be rotary, linear, or a combination of the two. For assistance in concretizing the finished equipment, specially-built actuators can combine or sequentially make these motions.

9. Find out if your actuator should have a specific precision level

Different actuators have varying degrees of precision. For instance, pneumatic actuators are used to construct air brakes since air pressure is adequate for starting and stopping motions.

Other actuators, such as those driven by hydraulics, have a more comprehensive range of movement variations. Any industry that demands high accuracy for operational success and safety should consider the relevant movement actuator types.

10. List down all safety and environmental concerns

When selecting an actuator for your equipment, safety is another aspect to consider. Care should be taken in locations with high temperatures or potential electrical or thermal risks while using electrical or thermal actuators.

Operating electrical actuators, for instance, adjacent to a water body without sealing or other safety precautions may pose a risk to one's health. You must also consider each actuator's environmental impact if your business is dedicated to having a smaller carbon footprint. Electrical actuators typically leave very little to no carbon footprint.

Additionally, there are particular rules that industrial actuators must abide by in specific locations. For instance, areas with a lot of combustible gasses should follow the guidelines of the National Electrical Manufacturers Association (NEMA).

What it takes to maintain an IoT actuator

Every piece of machinery needs upkeep. The IoT actuator is no exception. Taking care of your actuators can avoid major shutdowns, risks, or productivity loss. The following general advice will help you maintain the health of your actuators:

1. Regular inspection

Regular visual inspections of your equipment will help you spot any potential actuator problems early on. To check for deterioration, a mechanic with an acute eye is required, or IoT sensors can be deployed to share real-time information about the same.

2. Replenish and replace

Sometimes cylinder fluid needs to be replaced in hydraulic actuators. Always do a secondary inspection for leaks and indicators of low hydraulic fluid levels. Replace any damaged or loosened nuts, bolts, coils, or screws along with your actuator parts.

3. Measure performance data

Actuators may not always display obvious malfunction symptoms, but performance can often point to a problem. If you want to identify more severe issues, automated output computation and graphs may be required.

Hardware Design For IoT Projects: A Complete Guide

Access the GuideLearning the science behind IoT actuators

A typical IoT system is made up of a three-layer architecture. Layer one comprises wireless sensors and actuators. Layer two contains analog-to-digital data conversion and sensor data aggregation systems. Lastly, in layer three, the data is leveraged to enhance the IoT application. Now, let us study these three layers in detail:

1. Physical

This one is easy to understand. Sensors collect the data from the environment and convert it into valuable data from which one can glean actionable insights. Some core examples that produce an avalanche of data include air quality sensors, home voice controllers, water level detectors, and so on. As a business, you must have a definite system to make something out of the data fetched and organized.

One way is to immediately process some of the data, which is time-sensitive, to avoid network clutter. This includes threat detection, abrupt shutdowns, immediate crash statistics, and so on.

2. Network

You see, the data collected from actuators is still very raw. It needs to be organized and converted into digital streams for data processing. This is where data acquisition systems enter the picture, helping you convert analog waveforms into digital values - apt for processing. On the other hand, the IoT gateway receives digitized data and routes it over wired LANs, WiFi, and the internet.

3. Application

This layer is accountable for delivering application-specific services to the user. Once the data has been organized, cleaned, and reviewed, the information can be fed to the server for due analysis and application in new products or services.

Real-life examples of actuators in IoT

Actuators are an integral part of the IoT ecosystem and have been used long before IoT became a buzzword. Perhaps, these real-life examples of actuators will ring a bell:

1. Escalators

Originally known as "revolving stairs," the escalators' motion is because of the actuating mechanism, which obtains its input from the motion sensor. Once the sensor detects the movement, it activates the actuator that kickstarts the movement of the escalator belt.

2. Sliding doors

These are one of the most popular examples where one can experience the functioning of a real-life actuator. The actuators used here get their input from motion sensors. Whenever a sensor detects a movement, it activates the actuator, resulting in the panels of the sliding doors moving sideways - basically, open and shut.

3. Braking system

The advanced braking systems used for stopping moving vehicles (e.g., cars, buses, trucks) comprise pneumatic actuators. Such brakes are also known as air brakes as they improve the optimal use of the allocated space and promote power conservation.

4. Windshield wipers

These use linear actuators. The vehicle's battery is connected to the wiper switch, which works in sync with the wiper motor. On the other hand, the motor is attached to the actuator and the wiper blade. The entire arrangement forms an electrical circuit that operates the movement of the windshield wipers. When the wiper gets switched on, that activates the actuator, inducing linear and periodic motion of the wiper blades.

5. Car seat adjustments

Do you wonder how easily you can move a car seat forward and backward with the help of electrically powered motors? Whenever you turn on the switch placed on the side, an electrical signal flows through the circuit wires to power the motor, which, in turn, acts as the actuator and controls the seat's movement as long as the circuit is complete.

The Synergy of Sensors and Actuators in IoT

The true power of IoT lies in the seamless integration of sensors and actuators. This synergy creates a closed-loop system that can:

1. Sense: Gather data from the environment

2. Analyze: Process and interpret the data

3. Decide: Determine the appropriate action

4. Act: Use actuators to effect change in the environment

Are You Ready to Boost Efficiency with IoT Actuator Integration for Your Equipment?

Let's Get StartedOver to you

In a nutshell, actuators are devices that manipulate the physical environment, such as the temperature control switches used in smart homes. Actuators take the electrical input and convert it into tangible action.

Naturally, actuators collect an enormous amount of data, which can be valuable and useful to a business once it has been organized and appropriately processed. Simply put, IoT is not just a single technology; it is an amalgamation of many deeply connected ones.

If you want to know more about how actuators work in the world of IoT or want to kickstart an IoT app development project of your own, wait no more.

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a customized roadmap and strategies to leverage IoT for custom actuator solutions.