Table of Content

With a dynamic supply chain, the food industry is considered one of the world's most complicated sectors. The burger you enjoy may have gherkins from Turkey, cheese from Switzerland, and ketchup from Belgium. That is the beauty of globalization!

However, there is a dark side to food, i.e., wastage. According to FAO, 1.6 billion tons of food is wasted each year globally. This is a problem in terms of the economic losses for the food industry and the impact waste has on the environment.

The statistic also highlights another aspect of the sector: the transportation of perishable goods like milk, vegetables, groceries, and bread using refrigerators or reefer trucks.

The same holds true for the pharmaceutical and medical sectors. Biological products such as vaccines, hormones, and blood samples, devices such as diagnostic reagents and implants, and medical gasses and drugs require strict temperature control to maintain their freshness and quality.

However, during transit, there may arise issues with temperature regulation inside the vehicle and exposure to environmental factors such as light and humidity, affecting the goods.

So which industries have the highest business losses in transporting perishable goods?

Simply put, those that move around products with a limited shelf-life and/or requiring strict temperature control get negatively affected. Such industries are:

1. Food and beverage

Fresh produce, dairy items, and frozen foods require strict temperature control during transit to maintain their quality and safety. Any delay in transportation or failure to maintain the appropriate temperature can lead to spoilage and major financial losses.

2. Pharmaceutical

Vaccines, topical medicines, flammable gasses (for e.g. butane, acetylene, ammonia, and propane) and oral drugs need to be kept in an optimal environment - when being moved around - to maintain their efficacy and safety. Any exposure to extreme temperatures can render them ineffective.

3. Floriculture

Fresh-cut flowers have a limited shelf life and may wilt or degrade if not delivered on time. Delays in transportation can result in massive losses for the floriculture businesses, as the flowers may be unsellable by the time they reach their destination.

4. Agriculture

Fresh produce also has a limited shelf life and may get spoiled if not consumed promptly. Delays in transportation mean huge losses for the agriculture industry, as the fresh produce may be unsellable by the time it reaches the market.

5. Medical

Medical samples retrieved from a human's body must be transported at specific temperatures to maintain their quality. Any deviation from the required temperature can make the samples unusable, resulting in delayed patient treatment.

Transportation troubles: The main challenges of shipping perishable goods

When moving around perishable products, common issues typically associated with retail supply chain management are magnified as the former must be shipped in carefully controlled conditions. Moreover, with damage rates and shipping costs on the rise, creating an effective loss prevention strategy centered around visibility is more critical than ever for businesses involved. Here are the top four challenges of shipping perishable goods:

1. Temperature lapses

Easily spoilt products have to not only be kept below a certain temperature but also be shipped within a specific temperature range. For instance, if the temperature gets too cold inside a truck, this can be as damaging to the product as if the temperature was too hot.

Maintaining an ideal temperature range is difficult, especially when shipments have to change modes of transport between planes and trucks or ships and trains.

2. Inappropriate route selection

Factors such as temperature, humidity, and exposure to light can affect the shelf life of perishable items. If these goods are not transported and stored properly, they can spoil quickly, resulting in loss of quality and potential health hazards. It is, therefore, important to optimize the transportation route to ensure the safe handling of perishable goods.

3. Time constraints

Once a product has to be kept cold, the time needed for shipping becomes more crucial than ever. Every hour and day spent in transit cuts down on the amount of time perishable goods have on the retail shelf.

4. Liquid/gas leakage in vehicles

Tankers/reefer trucks are typically used to transport liquid or semi-liquid products, including food items and pharma items.

Maximizing the shelf life of packaged foods like milk is a continuous challenge because most perishable food items are moisture and oxygen-sensitive; even minor tampering with the packaging can ruin the product.

Then there are other gasses like acetylene, butane, and ammonia that can cause explosions that can be considered as perishable and potentially dangerous if not stored and handled properly.

Secondly, although tankers/reefer trucks vehicles are designed to be leak-proof, over time, they may develop leaks due to wear and tear, corrosion, or other factors.

This allows the perishable components to escape, causing liquid spilling/goods loss and environmental pollution. Additionally, fuel leakage can occur due to poor maintenance or improper loading of the vehicle.

Streamline Perishable Goods Transport With Our Tailored IoT Solutions!

Contact Us NowOvercome barriers in perishable goods transportation with the Internet of Things (IoT)

IoT is a technological framework that connects multiple devices through a cloud platform or private networks. In the past decade, it has gained much importance, transforming and simplifying processes in various industries such as automobile, manufacturing, transportation, agriculture, fintech, and oil and gas.

The use of IoT technology can specifically help combat the issues that come with perishable goods by providing real-time monitoring and control of the transportation process. The following section explores ways in which IoT helps when you move around such products - without hampering their integrity and quality:

1. Keep track and maintain product quality and temperature

Any business that transports perishable goods wants to prevent spoilage and maintain quality. To achieve the same, it is essential to confirm the goods are transported under appropriate conditions without letting any issues arise during transit and through:

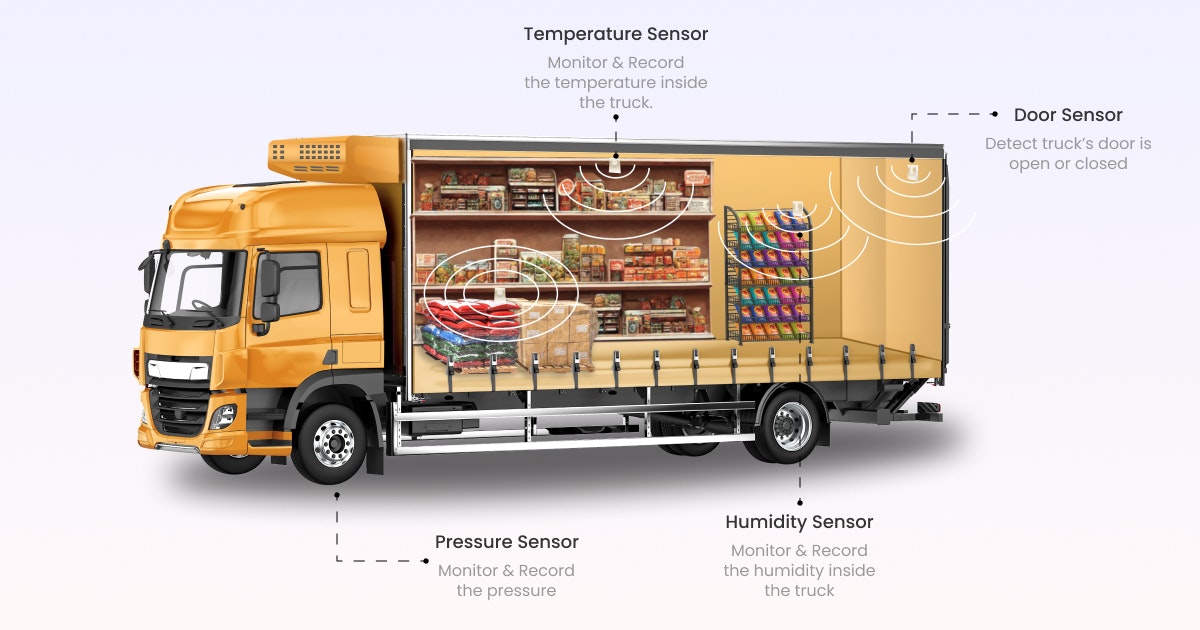

a. Auto-controlling the temperature of the refrigerated space

The temperature of the refrigerated space can be automatically controlled with IoT. Sensors can monitor the temperature and transmit the data to a central control system, which can regulate the temperature as needed to keep the perishable goods stored in an ideal environment.

b. Auto-controlling the humidity of the refrigerated space

Like temperature, IoT sensors can monitor the humidity levels and transmit the data to a control system, which can then adjust the humidity as needed to warrant that the products are fine.

2. Secure the vehicle outlet from where perishable liquid flows

There is always a risk of theft or loss of goods during transit. IoT can help address the problem by integrating smart IoT devices with refrigerated trucks to control the flow of perishable liquid.

In particular, flow sensors can be placed at the vehicle's outlet to detect the flow of liquid and transmit the data to a centralized system that compares the flow data with the expected flow and detects any discrepancies.

This way, an alert system actively sends notifications to relevant personnel and the control system about the type of mishap, enabling them to take immediate action.

For instance, smart sensors can be set only to allow a certain amount of liquid to be dispensed at a time or it can be set to enable dispensing when certain conditions are met, such as a valid ID or authorization from a supervisor.

This can help prevent unauthorized access or theft of the goods. Such precautionary measures can ensure the security and integrity of the perishable goods, minimize wastage and keep financial losses to a minimum.

An All-Inclusive Guide On The Top IoT Sensors In The Market

Access the Guide3. Use IoT sensors to detect leakage and avoid spillage

An IoT solution can help detect leaks or holes in the vehicle, helping ensure the safety and integrity of the transported goods, including liquids and gasses, and minimizing environmental pollution. Here is the technology works in the case of leakage:

a. Keep an eye on product parameters

IoT sensors attached to transportation vehicles can monitor specific product parameters such as pressure, temperature, flow rate, and liquid level. If any parameters exceed the acceptable range, the system can trigger an alarm, send an alert to the responsible personnel, and automatically shut off spillage.

Formaldehyde, for instance, is a colorless, smelly gas flammable at room temperature. Storing and transporting it in cold conditions is a given. If the temperature where it is stored starts rising, IoT sensors can notify and appropriate action can be taken.

b. Avoid fatal accidents and enable safety

In addition to preventing product loss, IoT can prevent fatal accidents due to leakage, such as a slip and fall injury or chemical exposure due to flammable gasses. Alternatively, the technology can automatically shut down the system if there is a pressure surge in the tanker, ensuring worker and public safety - without contributing to environmental degradation.

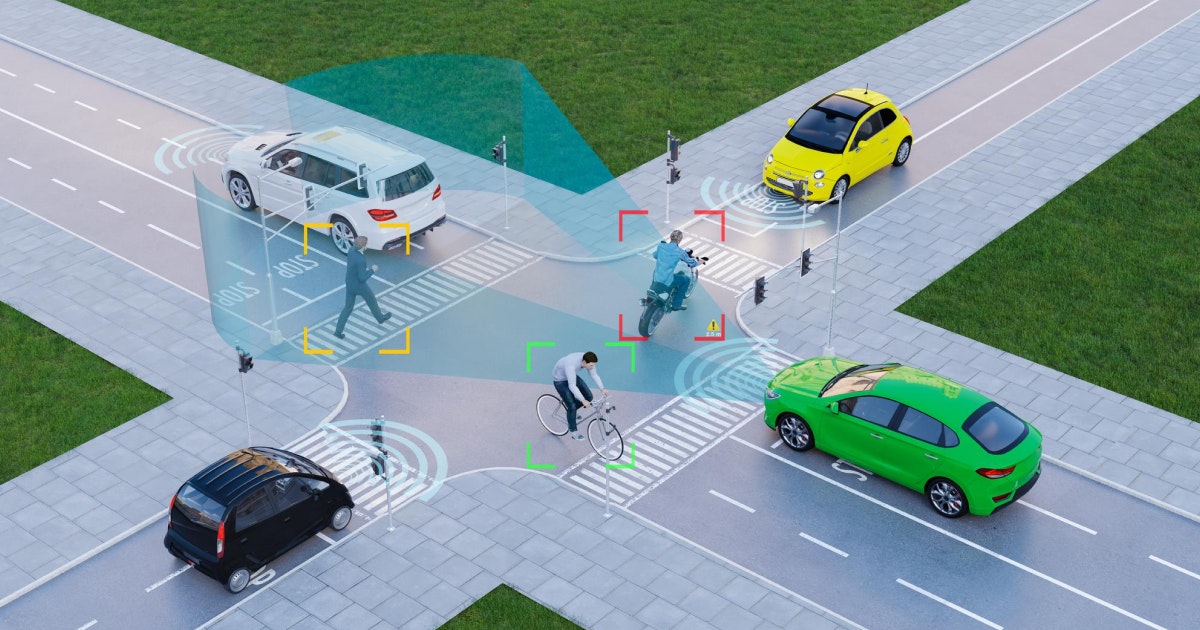

4. Optimize the transportation route for greater efficiency

IoT-enabled GPS tracking units placed on tanker/reefer trucks or containers can access real-time location data for optimizing delivery routes. By using routing software that takes into account factors such as traffic, weather, and road conditions, the system can identify the most efficient route to reach the destination.

The time-sensitive nature of perishable goods is also considered in the routing plan to minimize spoilage and ensure freshness upon delivery. In addition to enabling timely delivery, IoT technology aids in minimizing fuel consumption by reducing the distance and time spent on the road. This also saves business expenses and reduces transportation’s environmental impact.

How IoT is Solving OEMs' Challenges in Steel Manufacturing

Read NowOver to you

Without a doubt - IoT improves the efficiency of perishable goods transportation by a great margin. It makes it possible to track product location, temperature, humidity levels, and more in real-time and notify of any disruptions to the concerned personnel.

The technology helps minimize food waste by providing transparency and traceability throughout the transit. If you want to deploy a similar solution for your business, book your free consultation today with our IoT experts.

Intuz designs and delivers a range of IoT tools and solutions for transportation, and we can build you an IoT-based perishable goods transportation solution.