Table of Content

Level sensors, in general, are majorly used in different consumer, industrial and commercial processes. IoT-based liquid level monitoring projects are crafted in such a way that they can be used for remotely monitoring the level of liquid indoors and outdoors.

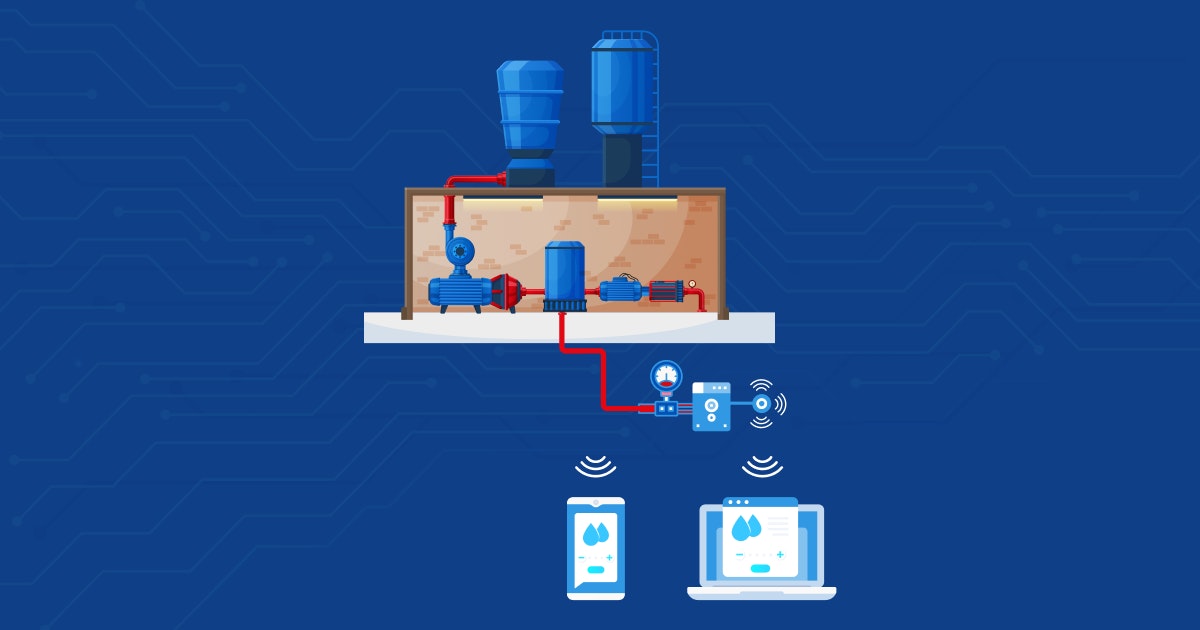

Basically, IoT liquid level monitoring systems help remotely monitor the liquid levels inside a tank or reservoir. Such a platform gives managers access to data on fluid levels, temperature, and Relative Humidity (RH) information.

Using such an IoT liquid level monitoring system can help manage inventory effectively for multiple locations. It gives them the visibility of their existing stock and helps control any thefts.

The examples of IoT-based liquid level monitoring

The examples of IoT-based liquid level monitoring

The IoT-run system has several applications, such as smart irrigation, leak detection, and usage of chemicals. The IoT-based liquid level monitoring platform helps achieve operational excellence by controlling wastage and preventing overflow or dangerously low levels of liquids.

The innovative system uses ultrasonic sensors, a microcontroller, an LCD screen to display liquid levels, a buzzer to trigger alarms, and a Wi-Fi modem for transmitting data. The dashboard offers a graphical view of the containers to ease the monitoring process.

Let us look at how IoT-based liquid-level monitoring systems can empower businesses by offering them better control over their resources.

Upgrade to Smart Liquid Monitoring with Custom IoT Solutions!

Let's Get StartedSmartphone-based liquid level monitoring system

Industrial plants use tanks to contain various liquids that are generally expensive and may be hazardous. It is, therefore, necessary to maintain optimum liquid levels for different operational processes, which makes it imperative for business owners to monitor fluid levels at all times.

If a liquid level in a tank is not appropriately monitored, it could overflow onto other surfaces and cause an accident. Deficient levels of liquid may cause damage to the vessel and hinder operations as well.

Liquid-level monitoring systems help address the challenges faced by organizations. It provides them with the required information in real time. The selection of IoT devices and sensors in a fluid-level monitoring system is based on factors such as:

Properties of the liquid

The geometry of the storage tank

The construction material of the tank

Pressure to be maintained in the storage tank

Temperature range of the liquid to be monitored

However, one of the most popular liquid level monitoring systems uses ultrasonic level detectors. They can be easily constructed and connected to a smartphone to serve as a dashboard, allowing you to keep track of the liquid levels in real-time.

Circuit and working

The IoT-based monitoring system has two main components. A transmitter unit modeled using Arduino Uno, an HC-05 Bluetooth module, and an HC-SR04 ultrasonic sensor module. The other component is a receiver unit

It can be as simple as your Android smartphone, and you can enable it to read the data by installing an Android app. The MIT App Inventor can be used to build a customized level monitoring application for the project.

Any smartphone with Android Lollipop v5.0 or above can be used in the model. The circuit begins with the HC-SR04 ultrasonic sensor module that provides a 2cm to 400cm non-contact measurement function.

It delivers data with an accuracy of up to 3mm. It transmits data to Arduino Uno, an AVR ATmega328P microcontroller-based development board. The board has six analog input pins and fourteen digital I/O pins.

Empowered with a 32 KB ISP flash memory, 1 KB EEPROM, and 2 KB RAM, the board acts as an interface for the ultrasonic sensor module and the HC-05 Bluetooth module.

Construction and testing

Start by assembling the circuit by placing the ultrasonic sensor at the top of a test container that acts as your fluid tank or vessel. Add the liquid for which you need to monitor the level.

Next, activate the Arduino Uno board using the 'smart_water_level.in' source code. You have already installed the 'Level Monitoring' application on your Android smartphone. Now you need to switch on the Bluetooth on it.

Upon powering the transmitter side, you can pair the HC-05 Bluetooth module with your Android smartphone using the default passkey as '1234' or '0000.'

Once the devices are successfully paired, you need to connect the 'Level Monitoring' app on your smartphone with the HC-05 device. It can be done easily by clicking the Bluetooth logo in the app and selecting the serial communication device from the list of Bluetooth devices detected by your smartphone.

After a successful connection, the Android application will display "Connected" on the screen and start showing water level control data in test tanks by processing information received from the transmitter side. You can check voltages at different levels and test points to check the system's accuracy.

Remotely manage through web and mobile apps.

The liquid level monitoring application can be accessed over both desktop and mobile devices. Once deployed at a remote location, you can use the web or mobile application to manage the liquid levels.

Similarly, if the monitoring setup is deployed in multiple locations, it can be controlled from a centralized location. Using a powerful IoT application will ease the monitoring process and provide actionable insights.

It can also be integrated with other automation platforms to start or stop processes based on triggers to allow you to make the most of your IoT-powered liquid level monitoring system.

What are level monitoring solutions?

A liquid level monitoring solution is an innovative system that informs the users about the levels of liquid in a specific area or container and will prevent it from overflowing.

Level monitoring solutions help measure and monitor liquid levels inside a tank or reservoir in real-time. These easy-to-use tools use sensors to gather the information transmitted over the IoT network for storage.

Business owners or managers can view the liquid status over their mobile phones and desktops. It gives your business the advantage of managing inventory levels and continuous monitoring fluid levels in multiple locations simultaneously.

Use cases of liquid level monitoring platforms

Use cases of liquid level monitoring platforms

Features such as geo-location help real-time decision-making, while historical data reports aid long-term business planning. Here are the top five use cases of a liquid level monitoring solution:

1. Fuel tank level monitoring

An IoT-based liquid level monitoring solution helps you monitor and control fuel levels in both mobile fuel tanks such as diesel tanks and fixed tanks at the gas station. Managers can remotely keep stock of fuel levels in real-time.

The primary benefit of deploying an IoT-based liquid level monitoring solution is scalability. It can cover the entire fleet as you grow, and you can even downsize the deployment as per your need. It allows you to optimize the inventory levels to save time and money.

2. Water tank level monitoring

An IoT-based liquid level monitoring solution enables you to monitor water levels in your water tanks in real-time. The system uses IoT sensors to alert you when the tanks fill up to a prescribed level or run out.

You can set threshold limits for the solution to trigger an alert for both when the tank is empty and full. It helps avoid wastage of water and corrosion of tanks due to water spills.

The data collected by the IoT device allows for better management of resources, such as electricity consumption and human resources for manual checks.

3. Smart irrigation

The IoT-based smart irrigation system is an end-to-end solution for the agriculture industry. It ensures the right water level is used for irrigating crops and that you never run out of water.

Suitable for all types of irrigation needs, an IoT-based liquid level monitoring solution offers real-time insights into the moisture level of soil and the water availability for motors. It will ensure that you do not have to worry about motors running out of water and burning out.

The automated system maintains the water level and raises an alert regarding the situation. Depending upon the instructions set out for each situation, the motors can be switched off automatically to save power and unnecessary running of the motors.

4. Mobile tanker level monitoring

Tankers carrying any fluid can be tracked using remote sensors. The liquid level in them can be monitored through the IoT-based mobile tank monitoring system. Different transit regulations apply to different liquids like water, fuel, or chemicals. An IoT-based liquid level monitoring solution enables you to monitor fluid levels and temperature.

Liquids transported in movable tanks are stored in special compartments to hold them securely throughout the journey. Intelligent transportation solutions make sure the levels are within the threshold.

An IoT-based liquid level monitoring solution helps ensure the safety of the liquid and prevents accidents on the highways as some materials being transported might be hazardous materials.

5. Wireless tank level monitoring

An IoT-based tank level monitoring system is designed with wireless sensors and devices, allowing for greater reading procedures flexibility. Apt for monitoring liquid levels in a tank, the low complexity wireless architecture makes troubleshooting easier for you.

The IoT solution has been designed to reduce the functional complexity of an industrial control room. Providing information in real-time makes reading procedures more flexible and streamlines operations.

The horizontal scaling benefits for industries allow them to conduct immediate troubleshooting. Managers can make data-driven decisions easily and control hardware and implementation costs. It is a low-cost solution that empowers companies to address their changing business requirements.

Boosting operational excellence

Industries like oil and gas and chemicals depend on their tanks and receptacles for storage and operations. They can use remote IoT monitoring solutions to elevate operational excellence and avoid downtime.

As a part of automation infrastructure, liquid level monitors in plants can conduct operations automatically. This helps increase production rates and predict probable malfunctions resulting in improved efficiency.

Types of alerts generated by the IoT-based liquid level monitoring solution

Alerts generated by the IoT-based liquid level monitoring solution

An IoT-based liquid level monitoring solution involves mounting ultrasonic level sensors in your tanks that calculate the fluid's distance to determine the fluid level and send the data to an IoT gateway.

This data is stored in the cloud and presented on your IoT-based solution dashboard as the fluid level in the tanks. Besides the real-time information on your dashboard, you can get advanced analytics for informed decision-making.

Defining threshold limits for the fluid levels allows you to manage inventory as an alert is triggered whenever the level goes below or beyond the prescribed limits.

An IoT-based liquid level monitoring solution's dashboard is accessible through desktop and mobile devices, while notifications are sent through the app, SMS, and email. The raw data is processed to offer the following information:

1. Fill level alerts

These alerts are generated when the fluid level in the tanks exceeds or drops beyond the threshold. You can automate the motor control to ensure the right levels are maintained. So, when the level drops, the motor switches on to maintain inventory levels. Whereas when the level rises, it is switched off to avoid overflow.

2. Inventory alerts

You can set an alert for the minimum inventory level to ensure you never run out of it. In the case of multiple tanks, the inventory data from all would be calculated to give you the total inventory levels. You can automate the inventory procurement using this information.

Curb Your Air Pollution Levels With Smart Air Quality Monitoring Solutions

Learn Now3. Theft alerts

Controlling the theft of liquids such as water, oil, and fuel is very tough, but an IoT-based liquid-level monitoring solution keeps track of your usage data. It alerts you regarding any anomaly, along with the exact data related to the event. You can use the information to prevent theft within the premises and during transit.

4. Temperature alerts

Maintaining the temperature of chemicals and flammable liquids is mandatory to avoid accidents. The temperature of liquids may vary due to transit and other external factors such as changes in weather conditions and pressure.

You can set a temperature range and receive notifications upon any deviations in temperature. It helps comply with regulations and prevent accidental fires.

Ready for Precision IoT-Powered Liquid Monitoring?

Let's ConnectOver to you

The implementation of IoT in liquid-level monitoring is an excellent opportunity for organizations handling water, oil, fuel, and liquid chemicals as raw materials or products. It provides them with a much-needed solution to mitigate the risk of theft and accidents.

You can ensure an uninterrupted supply of inventory with regular level alerts and forecast consumption using historical data. So, what are you waiting for? Create a new range of personalized IoT solutions that work in sync with your machinery.

Let Intuz IoT experts collaborate with your hardware designers to launch IoT-powered apps for liquid-level monitoring. Whatever your business requirement, we will bring your IoT application development project to life faster.

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a customized roadmap and strategies to leverage IoT for smart liquid monitoring.