Table of Content

Ensuring a dependable and high-quality power supply is necessary for the smooth functioning of critical establishments, such as hospitals, airports, data centers, and military offices. Failure to provide steady and dependable power results in disastrous consequences, such as business disruption, public safety, infrastructure damage, and more significant health risks.

Sure, installing backup generators can help in this regard. However, proper maintenance and operation of these generators are crucial for their effectiveness. You see, the average failure rate for power generators is approximately 2% per year.

The cost of a generator failure can range from $25,000 to $1 million or more, depending on the failure's severity and the generator's size and type. No business should have to deal with such high expenses! Therefore, key concerns, such as remote monitoring of the fuel tank, total load, and battery voltage need to be addressed for optimal electric generator monitoring.

Common problems with power generators

One of the primary problems that generators can experience is leaks. Fuel, coolant, and oil leaks can occur. However regular maintenance checks can help prevent them. Inspecting the generator periodically can catch these issues early and avoid further damage.

Fuel leaks are a common problem when the base tank is overfilled or the fuel pump system malfunctions. To ensure proper refueling, it is best to have a qualified maintenance professional handle it. On the other hand, coolant leaks occur in the block heater hoses, which can wear out quickly due to the high temperatures generated by the heater.

Low coolant levels can lead to engine overheating and cause damage to other components, so it is essential to inspect the generator for leaks if coolant is added frequently. Dead batteries and control panel malfunctions can also cause generator problems.

Although routine maintenance can help extend battery life, control panel issues are often the result of human error. Exhaust system issues such as leaks or blockages can cause increased emissions and reduced performance.

Problems with the air intake system can result in the engine suffering from reduced power output and increased emissions. Finally, block heater wear can cause the generator to fail and may require installing a replacement part.

Let's Upgrade Your Generator by Integrating Advanced IoT!

Let's Get StartedIoT solutions for resolving power generator problems

The Internet of Things, or IoT, is a collection of technologies and associated business processes that enable various devices to communicate information about their status to other systems. This creates new opportunities to analyze and act on this information.

In the game of uninterrupted power supply, the adoption of IoT applications has evolved with the availability of new technologies to improve asset optimization and control, enhance safety, manage the grid, and ensure reliable electricity. Adding to that thought, here are six ways IoT comes in handy for resolving power generator optimization problems:

1. Stable power supply

Power generators with electric starters rely on a battery to crank the engine. Battery failure can result from age, lack of use, extreme temperatures, and terminal corrosion. Voltage and frequency fluctuations can be detected by IoT sensors, which can then adjust the generator's output to correct any irregularities.

This helps ensure a stable power supply and prohibits damage to connected equipment due to voltage and frequency fluctuations. Cooling system problems can also affect the electrical generator performance.

For example, if the generator’s cooling system is clogged or malfunctioning, the engine may overheat, causing a reduction in power output or even a complete shutdown. IoT sensors can detect these issues and alert maintenance teams before they cause any damage or disruption to the power supply.

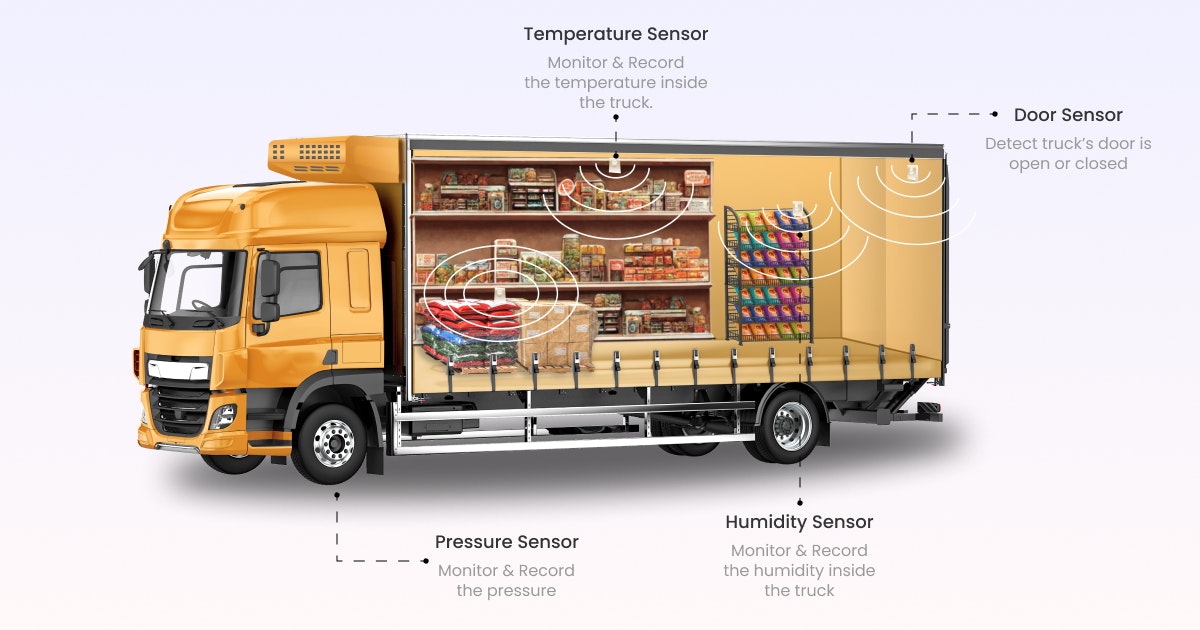

2. Real-time fuel monitoring

This is an essential feature that helps restrain fuel-related issues in power generators. IoT sensors can be installed in the fuel tank to monitor the fuel quality and detect any contaminants that may have entered the fuel, such as water, dirt, debris, or other particles.

For instance, water contamination is a common problem when the fuel tank is exposed to moisture, leading to corrosion and rust formation.

IoT sensors detect the presence of water in the fuel tank and alert operators when water is detected, sending alerts via email or text message when levels exceed pre-set thresholds. This enables operators to take immediate action and thwart damage to the generator.

Dirty fuel is another problem that can affect generator performance. Fuel can become contaminated with dirt, debris, or other particles that can clog fuel filters and damage fuel injectors, thereby raising the need for IoT power generator fault detection.

IoT sensors can monitor the fuel quality and detect the presence of contaminants, sending alerts when levels exceed pre-set thresholds. This allows operators to take corrective actions such as replacing fuel filters or draining the fuel tank to stop further damage.

On the other hand, low-quality fuel or incorrect fuel type impacts the generator's performance. Low-quality fuel can have insufficient octane or cetane ratings, leading to poor engine performance, reduced fuel efficiency, and potential engine damage.

IoT sensors monitor fuel quality and ensure that the correct fuel type is used and meets the required octane or cetane ratings. This can help deter engine damage and ensure the generator runs optimally.

Top 25 IoT Development Boards In 2023 And How To Choose The Right One

Learn More3. Mechanical problems detection

Installing IoT sensors on power generators makes it possible to detect mechanical problems before they arise. These sensors can detect vibrations, abnormal noises, and other signs of mechanical issues, allowing maintenance personnel to take a measurable action before the problem leads to a breakdown, causing the business millions.

Moreover, based on historical data, IoT devices can predict the remaining useful life of the generator components. By analyzing the data collected from IoT sensors, algorithms can determine when components will likely fail and alert maintenance personnel to replace them before they cause a problem.

4. Preventable engine overheating

IoT sensors can monitor the temperature of the generator's engine and detect any anomalies in real-time. This helps obstruct engine overheating that causes permanent damage to the engine and even leads to a complete generator shutdown.

The IoT sensors can be set up to trigger alarms or notifications when the engine temperature exceeds a certain threshold, allowing the maintenance team to take immediate action before any serious damage occurs.

Additionally, IoT devices can automate the adjustments required to impede engine overheating based on predefined rules or machine learning algorithms.

For example, the IoT device can adjust the generator's load or automatically turn on the cooling system to maintain a safe operating temperature. This helps put engine damage at bay, optimizes the generator's performance, and reduces fuel consumption.

5. Advanced lubrication management

The lubrication, exhaust, and air intake systems are critical components of a power generator. Any issues with them can cause reduced power output, increased emissions, and even catastrophic engine failure.

With the help of IoT sensors, the lubrication system can be monitored for oil pressure, temperature, and oil level, among other parameters. This can help detect any issues with the lubrication system early on.

Additionally, IoT devices can automatically schedule regular oil changes based on usage patterns, reducing the risk of engine damage due to insufficient lubrication.

6. IoT-enabled battery status monitoring

IoT can help ensure the power generator's battery is always ready to start the engine when needed. IoT sensors constantly monitor the battery's voltage, temperature, and overall health and alert the maintenance team if the battery is weak or needs to be replaced.

It can avoid situations where the generator fails to start due to a dead battery, which can be a significant problem in emergencies where backup power is required immediately.

Moreover, IoT can optimize the battery's performance and extend its useful life by providing insights into its use. The IoT sensors can detect usage patterns and automatically switch to alternative power sources to reduce the strain on the battery.

Leveraging Transformer Monitoring with Industrial IoT

Learn moreAdvantages of IoT in power generator maintenance

IoT offers numerous advantages for power generator maintenance. By leveraging real-time data analytics, the technology helps businesses avoid costly repairs and extend the lifespan of IoT power generator monitoring systems. Here are the top four IoT advantages:

1. Worker safety

IoT increases safety by enabling remote monitoring and control of power generators. Operators can monitor the generator's status from a safe distance and take action whenever necessary. This can help prevent accidents and injuries and improve overall safety in the workplace.

2. Improved reliability

Businesses can proactively detect and address issues before they become major problems using IoT sensors and monitoring tools. This minimizes unexpected downtime and ensures that power generators are always available when needed.

3. Extended lifespan of power generators

By proactively detecting and addressing issues, businesses can counteract premature wear and tear and avoid costly repairs. This can maximize the return on investment for the power generator and ensure that it continues to provide reliable power for years to come.

4. Lower maintenance costs and minimized downtime

Rather than performing routine maintenance on a fixed schedule, businesses can use IoT data to determine the optimal maintenance time based on the power generator's actual usage and condition. This can reduce unnecessary maintenance and minimize downtime.

Cutting-edge Industrial IoT Solutions and Development Services Company!

Explore servicesOver to you

The global energy demand is predicted to increase by around 5% each year, resulting in a rise in the size and complexity of equipment connected to the power grid and an increase in power quality disturbances.

This means businesses will rely more on consistent and dependable clean electricity. By utilizing advanced power quality monitoring technology, industrial equipment owners can anticipate experiencing fewer instances of equipment malfunction or deterioration and enjoy the benefits of pure power.

The combination of reliable power generators and IoT technology has the potential to significantly improve the reliability and efficiency of power supply while also reducing maintenance costs and improving safety.

As IoT technology continues to evolve, there is significant potential for even more advanced capabilities to be developed, further enhancing the performance and reliability of power generators.

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a customized roadmap and strategies to leverage IoT to make smart power generators.