Table of Content

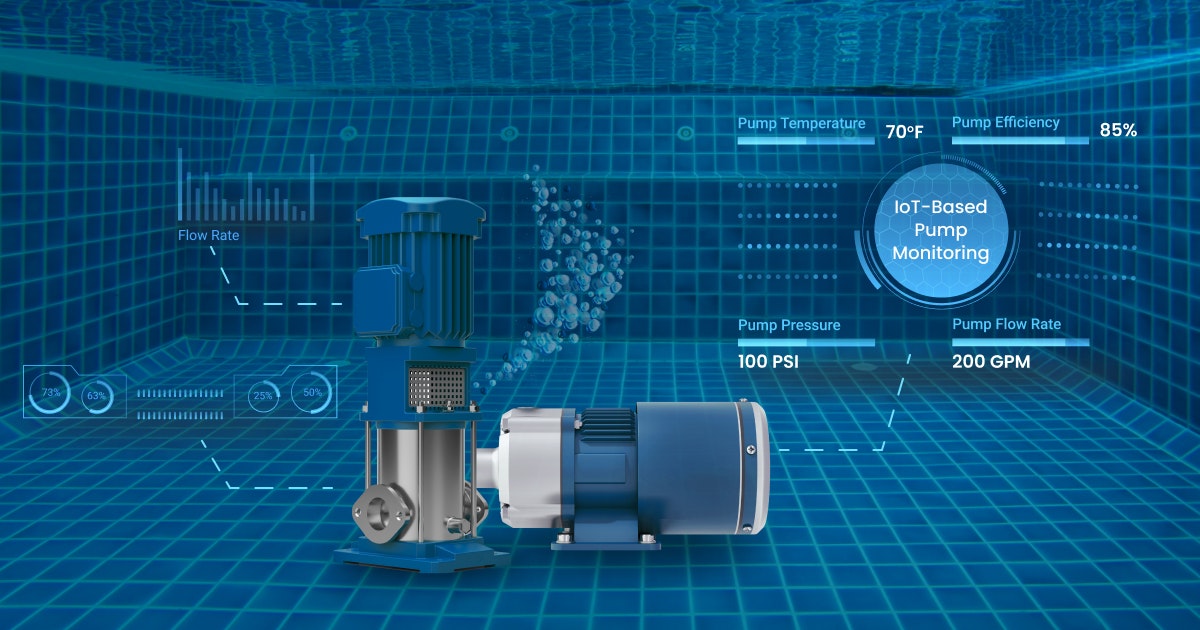

What is an IoT-based Fluid Monitoring System?

For chemical storage facilities, safety is always the topmost priority. Handling and storing dangerous and highly flammable chemicals involve several risks such as accidents, injuries, and leakages. It is here that an IoT-based fluid monitoring system comes into play! These systems provide automatic detection of various industrial fluid parameters such as temperature, flow, and pressure. Fluid monitoring systems provide real-time and actionable insights about the status of chemicals, helping businesses to enhance overall operational efficiency. When equipped with real-time data, technicians can take appropriate actions to prevent problems such as spillage, fluid depletion, leakages, and uncontrolled usage.

How Leveraging IoT-enabled Solutions Alleviate Fluid Monitoring for Chemical Storage?

Manual fluid monitoring methods, especially in the chemical industry, are time-consuming and susceptible to miscalculations and errors. This makes it challenging to diagnose the problem and address it promptly. Contrary to this, smart monitoring of fluids gives accurate data and a complete picture. This helps the chemical industries to increase equipment efficiency and improve product quality. Here’s how IoT solutions mitigate the risks involved in fluid monitoring in the chemical industry:

- Real-time monitoring of fluid quality parameters

- Remote leakage monitoring

- Alerts and notifications on mobile apps

- Sharable and actionable insights

- Preventive maintenance

Upgrade Your Chemical Storage with IoT-Powered Smart Fluid Monitoring!

Let's Get StartedIndustrial Fluid Monitoring: Challenges and Complexities

Storage and transport of hazardous chemicals pose inevitable risks. Recently, a rail containing dangerous chemicals, derailed in East Palestine Ohio causing severe soil, water, and air pollution. History has shown that such accidental spillage not only causes irreparable damage to human lives and ecology but also results in serious economic loss. Regular monitoring of the vital parameters of fluid management is the key to mitigating such risks. However, tracking discrepancies in these parameters can be daunting and time-consuming.

Collecting and sending fluid samples for laboratory examination can take months. Also, the analysis reports might not offer real-time insights which can affect the storage decision and maintenance costs. Here, we will navigate through some of the common complexities in fluid monitoring:

Keeping the Fluid at the Right Levels

Chemical plants use storage tanks to contain different chemicals. These chemicals are not only extremely harmful and toxic, but they come with a huge price tag. Spillages or leakages can cause immense damage to the landfills, ocean, and human well-being. Therefore, it becomes absolutely necessary to maintain optimal fluid levels to prevent leaks or chemical spills.

However, manually tracking the fluid levels could not provide useful insights, making it difficult for technicians to ensure the tanks are overfilled. When fluid levels aren’t managed properly, it could overspill presenting serious health and safety hazards.

Maintain Optimum Temperature

Maintaining optimal and uniform temperature is one of the most crucial parts of safe chemical storage. If the temperature goes above or beyond a prescribed range, it can hurt the chemical composition, making it volatile and even dangerous. Low temperatures can freeze the fluid causing the storage container to split or crack, posing the danger of leaks and pollution. Similarly, high temperatures can cause certain flammable chemicals to catch fire resulting in immense loss of lives and property.

It is, hence, vital to control and monitor the temperature to ensure chemical compositions aren’t altered. A traditional approach to tracking the differences in temperature doesn’t provide precise analytical data affecting productivity and operational efficiency.

Keeping Fluid Pressure Under Control

Maintaining fluid pressures within permissible limits is pivotal to ensuring chemicals are stored safely. While there are pressure regulators placed at different locations to balance the pressure level, manual monitoring doesn’t always provide desired outcomes. Keeping fluid pressure within the threshold is critical to prevent machinery blowouts, equipment damage, and even system breakdown. This results in unproductive shutdowns and huge economic losses.

Control Humidity to Prevent Contamination

Ensuring the quality of sensitive fluids and chemicals during storage and transportation is a significant process.

When the temperature, fluid level, and pressure change, the chemical stored inside the tank starts drawing and retaining moisture. The humid atmospheric air contains detrimental levels of moisture and dust particulates that contaminate the stored fluids and chemicals.

Regulating Fluid Flow Rate

Fluid flow control is defined as the amount of fluid circulating in a given time. It is important to regulate the liquid flow or pressure to ensure the chemicals are stored and transported safely. Flow control is an essential part of chemical plants and storage to maintain the quality of the end product. Variations in flow rate at any point can cause spillage and corrosion. Moreover, controlling the flow rate is a must to remain compliant with stringent environmental and safety regulations. However, keeping track of the flow rate through physical examination is vulnerable to miscalculations and blunders.

Monitoring Chemical Composition and Quality

Storing chemicals for a long time can alter their composition posing health, environmental, and safety hazards.

Therefore, it is vital to track levels of certain substances of potential concern such as Formaldehyde, Vinyl chloride, Methylene chloride, and Benzene. Imbalanced chemical composition can ruin the quality of the product and prevent dangerous gas or liquid leakages.

Actionable Real-Time Insights: How Smart IoT-based Fluid Monitoring Give Competitive Edge

Actionable and in-depth insights generated by smart IoT-based solutions reduce presumptions and hypotheses to ensure efficient and safe chemical storage. Furthermore, with this information, technicians can diagnose potential issues and take preventive measures to reduce downtime and operational risks. Here’s how smart IoT-based solutions address the challenges in fluid parameter monitoring and help businesses:

Instant Alerts to Ensure Fluid Levels are Within Threshold Limits

Get alerts when fluid levels go above or beyond threshold limits with IoT-based smart monitoring solutions. IoT sensors collect real-time data to calculate the levels, chemical composition, and temperature of the fluids. In case of anomalies, the concern teams are sent instant alerts notifying them about a potential issue. With this information, they can analyze the situation and take preventive steps to eliminate the risk of contamination, spillage or maintenance shutdown.

Real-Time Fluid Monitoring - Anywhere, Anytime

Smart IoT sensors mounted within the storage containers can sense the parameters such as levels, temperature, and humidity. The sensors send the raw data to a centralized hub and convert it into meaningful and actionable insights and displays on the dashboard. Technicians remotely examine this real-time data via the dashboard. They can easily detect any variation in the parameters and gauge the situation. This information helps them to track the fluid quality and quantity from anywhere and take quick actions to fix a potential problem.

Businesses can use remote monitoring to prevent chemical leaks and possible damage to the equipment and environment.

Data Visualization Made Easy with Centralized IoT Dashboards

An Industrial IoT dashboard displays relevant information about fluid monitoring parameters. These dashboards help the technicians to track the performance of the storage containers and fluids from a remote location. Moreover, the dashboard display alerts and provide situational fluctuations in the parameters based on predefined thresholds. Furthermore, dashboards can help to diagnose problems such as leaks, corrosion, spills or depleting levels to deploy maintenance teams on-site for troubleshooting.

No More Unscheduled Shutdown: IoT Preventive Maintenance

Equipment failures, fluid spillage, and leaks can significantly impact the environment, personnel safety, and business operations.

Hence, preventive maintenance becomes paramount. IoT-based preventive maintenance enables the technicians to accurately anticipate any inaccuracy in the fluid quality or parameter based on real-time data. Maintenance staff can be deployed immediately to fix any discrepancies in fluid quantity and quality. This ensures reduced unscheduled shutdown, machine failure, and spillage accidents.

Automated Temperature and Humidity Control

Properly managed temperature and humidity are key factors to ensure the safety and quality of stored chemicals.

As a part of the fluid monitoring system, IoT-based automated temperature and humidity can ensure key parameters stay within the prescribed limits. Technicians can control the temperature and moisture levels remotely to ensure chemical compositions stay intact and don't pose any threat to the environment and personnel safety.

Let's Implement IoT for Precise Chemical Fluid Monitoring!

Contact UsFinal Word

The deployment of IoT for smart fluid monitoring poses an excellent opportunity to track quality parameters to mitigate the risk of accidents, contamination, and operational inefficiencies. Want to create a personalized IoT solution to make fluid monitoring more effective?

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a complimentary strategy to develop and deploy IoT-based smart fluid monitoring solutions.