Table of Content

Grease, grime, and fluid build-up can adversely impact the performance of heavy machinery or equipment. Also, such machinery poses a serious threat to the life and limb of the employees. To deal with this, industrial cleaning and washing become pivotal.

Importance of Water Quality Monitoring in Industrial Washing & Cleaning Process

H2O is a key component in industrial cleaning and washing; therefore regular water quality monitoring becomes essential. Using poor-quality water for cleaning or washing machinery causes premature mechanical wear, corrosion, and abrasion of the metal surface. The gradual degradation eventually decreases productivity, causes frequent downtime, and adds up the maintenance costs.

Which Important Parameters to Consider for Industrial Water Quality Monitoring?

With regular water quality management, machinery remains in good condition and can positively impact the ROIs. Moreover, quality monitoring is critical to adhere to increasingly strict environmental and safety regulations. Here are some of the prominent parameters for monitoring water quality for washing and cleaning heavy machines:

Turbidity

Turbidity is one of the vital properties of water to determine its quality. In industrial cleaning and washing processes, high turbidity in H2O can lead to a gradual build-up of impurities such as silt, clay, and algae on the surface. This causes the filters in pumps or pipes to clog, contributing to the wear and tear of the machinery.

pH Levels

Higher pH means the water is alkaline, while lower pH makes it acidic. For effective industrial cleaning and washing, balanced pH levels are paramount. Lower pH causes corrosion to the metal surfaces, while excess pH value leads to the accumulation of mineral deposits. In any case, this severely affects the overall operational capabilities and longevity of machinery.

Temperature

Maintaining water temperature during cleaning and washing industrial equipment is critical to prevent long-term damage. Higher water temperatures provide a perfect breeding ground for microorganisms like bacteria and algae. It accelerates the fouling process in the heat exchanger, turbines, and piping system making them vulnerable to rapid wear and tear.

Alkalinity

The alkalinity level in industrial water determines its ability to neutralize acids. High alkalinity causes a build-up of calcium carbonate and bicarbonate ions on the surface of boilers, cooling towers, condensers, and pipes, speeding up corrosion. This causes premature damage to the machine further adding up the cost of maintenance and replacement.

Enhance Your Washing Processes with IoT-Enabled Water Quality Monitoring!

Explore SolutionsChallenges in Industrial Water Quality Monitoring

Maintaining the water quality for industrial cleaning and washing is vital to ensure the equipment functions flawlessly. However, monitoring water quality comes with numerous challenges. Traditional sampling methods may not provide accurate data, making preventive maintenance difficult. Here are some of the challenges that can affect the industrial water quality monitoring process:

Detecting Organic and Inorganic Impurities

Poor-quality water used for cleaning complex machinery escalates the deterioration of machines and equipment. However, detecting suspended solids like sediments, dirt, and organic matter in the water used for industrial cleaning and washing can be extremely difficult. If proper preventive steps are not taken to remove or control such impurities, they can form sludge on the surfaces affecting a machine’s operational capabilities. Besides, cleaning equipment and components of nuclear reactors produce wastewater loaded with lethal radioactive materials. When left untreated, radioactive material in water not only damages the machinery but also poses fatal health and environmental hazards.

Monitoring the Presence of Corrosive Materials in Water

Industrial water containing excessive salts, acids, or other corrosive materials causes scaling and sludge formation. This can affect the flow of H2O and other industrial liquids through pipes and pumps. Also, corrosive components cause premature leaks, breakdowns, and also possible shutdowns. Manual monitoring of these particles can be daunting as it may take weeks to get an analysis report. This not only makes it difficult to predict a potential issue but also causes delays in preventive maintenance.

Poor Water Quality Non-Adherence to Environmental Regulations

Inferior H2O quality in industrial cleaning and washing is not just detrimental to machinery’s health but also leads to severe environmental problems. Therefore, it is important to monitor industrial water quality to comply with the regulatory requirements for environmental safety. Failure to manage the industrial wastewater treatment and discharge processes can attract heavy fines and legal action resulting in the loss of the brand’s reputation.

Time-Consuming Manual Sampling Process

Gathering manual samples for quality examination is time-consuming. Also, manual sampling is prone to data inaccuracies and human errors. Manual sampling is generally performed at fixed intervals and hence cannot capture minor discrepancies in the data. Moreover, manual sampling requires collecting multiple samples from different locations, labeling them properly, and transporting them for analysis. Furthermore, as the physical samples are transported from one place to another, they are vulnerable to contamination and mix-up. Given these challenges, collecting manual samples cannot provide a precise and comprehensive picture of the industrial water quality. Therefore, it is necessary to employ smart water quality monitoring solutions for industrial cleaning and washing.

Inaccurate Analytical Data

No matter how advanced, every laboratory has some limitations as they are prone to human errors and inaccurate analytical data. Also, detecting low levels of water impurities is almost impossible using traditional ways. Lack of precise and real-time data analysis can affect the monitoring of water quality in industrial cleaning and washing.

Benefits of Advanced Industrial IoT for Water Quality Monitoring and Management

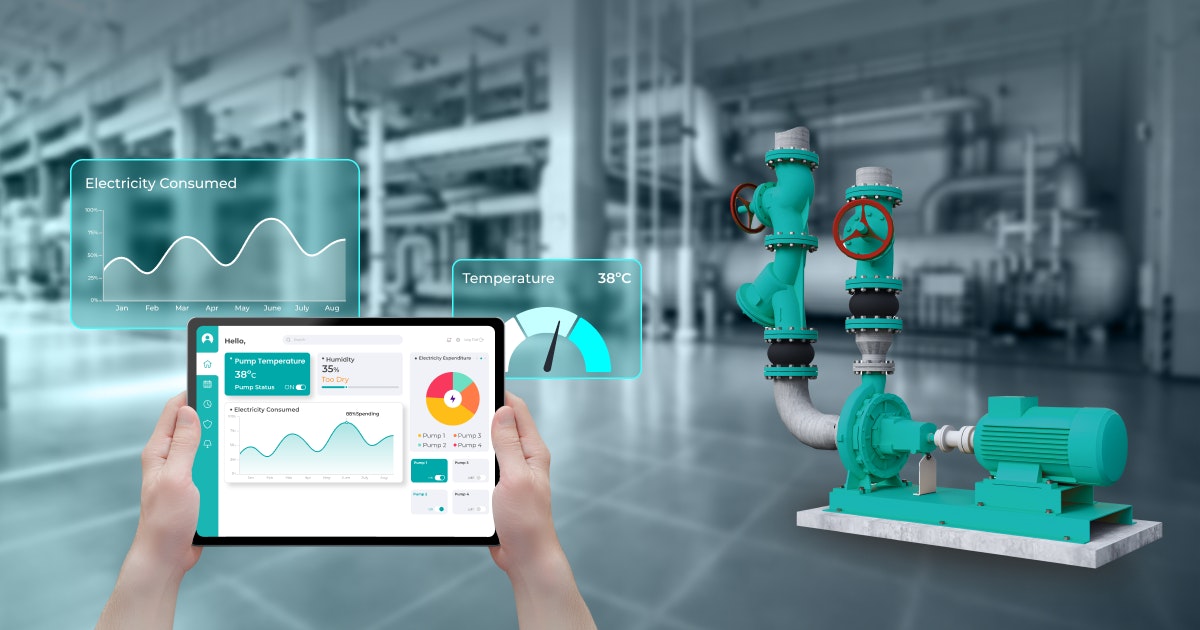

IoT solutions interconnect multiple sensors to collect, track and analyze water quality data in real time. IoT-powered solutions for industrial cleaning processes are designed to gather the latest water quality data. The industrial IoT sensors can detect even a minor variation in the pH levels, temperature, acidity, salinity, turbidity, and alkalinity. The data is transferred to a centralized cloud-based system for further evaluation and analysis.

Along with machine learning algorithms, IoT solutions can identify any discrepancies in the patterns that may point towards any fluctuation in water quality. This helps the organization detect possible issues early on and prevent water quality from deteriorating. Here’s how IoT solutions can make industrial water quality monitoring streamline and benefits your business:

Cutting-edge Industrial IoT Solutions and Development Services

Explore NowRemote Water Quality Monitoring

Remote monitoring is the key to maintaining water quality for industrial cleaning and washing. With advanced IoT-powered sensors at different locations, it becomes possible to keep track of H2O quality from anywhere. These sensors gather real-time data during the cleaning and washing process. If even a minor difference in temperature, pressure, flow, and pH is recorded. Based on this data, it becomes quick for the technicians to identify any glitch, damage, or potential leaks and take preventive steps. With predictive maintenance, the organization can alleviate shutdown or downtime and reduce the costly repair or replacement costs.

IoT Sensors to Detect Contaminants

Collecting manual water samples for analysis cannot detect possible contaminants early on. Using such water for industrial cleaning or washing purposes causes immense damage to the machinery and also adds up to the maintenance/replacement costs. With IoT sensors monitoring water quality parameters becomes seamless and quick. Any discrepancies in H2O quality parameters such as pH, alkalinity, and temperature is promptly recorded.

Water Quality Monitoring Via Intuitive Dashboard

For effective industrial cleaning and washing, water quality is supremely important. Poor quality water in cleaning and washing can cause corrosion, fouling, and scaling. Industrial IoT-based solutions offer an intuitive dashboard, facilitating remote monitoring of real-time data on water quality parameters. When a parameter falls outside the threshold, the maintenance team gets an instant notification. Technicians can immediately take control of the situation and identify potential issues, such as leaks or spills before the problem becomes too big.

Adherence to Environmental Regulations

In the long term, poor water quality in industrial cleaning and washing causes rapid surface degradation, mechanical wear, and abrasion. This compromises the machinery’s strength increasing the likelihood of accidents, spills, and leakages. Accidental spills and leakages pose a threat to the ecosystem and public health. IoT-enabled platforms allow technicians to monitor H2O quality during every industrial cleaning process. Maintenance staff can quickly detect traces of impurities or contaminants in the water. Also, they can identify possible surface damage, leaks, or spills and enable immediate troubleshooting. This allows you to adhere to environmental regulations and save costly replacement and repairs.

Let's Integrate IoT Water Quality Control Into Your Operations!

Contact UsTakeaway

Water is the most critical component of any industrial process. Therefore, it is crucial to continuously monitor and manage industrial water quality to ensure it doesn’t hamper crucial industrial operations. With advancements in IoT technologies, water quality management has become more streamlined, quick, and accurate. This has helped various businesses to save on unnecessary maintenance or repair costs.

If you are looking for a top-notch, scalable, and customized IoT solution for industrial water quality monitoring,

Book a Free 45-minute Consultation with Our IoT Experts Today! Get a customized roadmap and strategies to leverage IoT for water monitoring in industrial washing and cleaning processes.